Traditional Twist Drill Bits Vs. Annular Cutters

21st Feb 2019

BLUEROCK's magnetic drills are primarily designed to use annular cutters. Some models can use an adapter to use a drill chuck for twist drilling, but annular cutters are definitely the preferred method or making holes. Why?

TWIST DRILL BITS

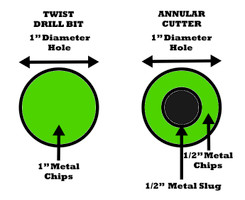

Traditionally twist drill bits have been and are still to some extent the tool of choice when it comes to making holes in metal. If a 1" hole is needed to be drilled in a piece of 1/2" steel, you'd generally step drill. What that means is using multiple standard twist drill bits. You might start with a 1/4" bit, step up to a 1/2" bit, step up to a 3/4" bit and finally finish the hole with a 1" bit. This essentially meant you were slowly chipping away at all of the metal within the boundaries of that 1" circle. This method takes time and considerable effort chucking up new bits every few minutes. Twist drill bits only have two cutting edges, require more cutting time, require a more powerful tool and use a slower feed rate when compared to annular cutters.

ANNULAR CUTTERS

Alternatively, annular cutters only cut along the outside edge of that 1" hole being made. They have no need to cut the inside of the hole, creating what's known as a metal "slug" when the hole is complete (which is untouched metal). Annular cutters use multiple cutting teeth that cut this outside edge on their generally 1/4" thick side walls. This translates to the removal of a smaller percentage of metal being chipped away. So basically, the larger the hole, the more efficient annular cutters become.

Additionally, due to the increased number of cutting teeth, annular cutters generally stay sharper 5-10x longer than traditional twist drill bits and drill more precise rounded holes (not oblong as the 2 sided standard bits). The one caveat to annular cutter use is that their size range starts at 7/16." With anything smaller than 7/16" there would be no hollow center in the cutter, negating the efficiency gains of annular cutters. So if you need to drill holes smaller than 7/16", you'd need to use standard twist bits.

HOW DO ANNULAR CUTTERS ACTUALLY WORK

Annular cutters generally use a pilot pin in the center of the cutter. Depending on your specific application and drilling set-up, that pin will also be in the same channel that lets cutting oil through the center of the cutter onto your work surface. That pin also acts as a centering guide as well as a "slug" ejector when the cutter breaks through the metal surface as most magnetic drills use a spring loaded backer in their weldon shanks.

CONCLUSION

If you have a lot of 7/16" or larger holes needed to be made in steel, you should give some serious consideration to annular cutters. Newer lightweight machines are being used with annular cutters everywhere from large manufacturing/fabrication shops to small farms or residential garages. They drill 4x faster, stay sharper 5-10x longer, consume less power, make less mess (due to less oily metal shavings) and can be efficiently used on small portable machines.

If you’re interested in our BLUEROCK Tools magnetic drills or annular cutters see the links below:

http://www.bluerocktools.com/magnetic-drills/